Conversion of Rice Husk to Value-Added Products

Addressing environmental challenges through collaboration under “Environment & Sustainable Development”

About

India is the second largest rice-growing country in the world. Rice plant shoot is composed of Straw 50 to 60 % and Paddy 40 to 50%. Paddy is composed of Brown rice (5 to 10%) Rice husk (~20%) and 70 % rice grain, which is extracted and the remaining husk and straw parts are discarded, used as land fill, burnt, or used as fuel. A large quantity of rice husk is also generated as a by-product in Rice mills during the milling process, which is difficult to manage and is used as a land-fill or as fuel, which leads to pilferage/wastage of a naturally produced valuable Biochemical and fine chemical products like cellulose and amorphous silica.

Objectives

To scale-up the production of amorphous silica and cellulose from rice husk/stubble and mature the Technology, which can have a large potential.

❖ To build 200 Kilogram/ Day rice chaff (husk)/stubble processing Semi-Pilot plant.

❖ To financially benefit marginal farmers.

❖ To help at least 1 Rice mill to partly manage large volumes of Rice husk storage overload.

Process Overview

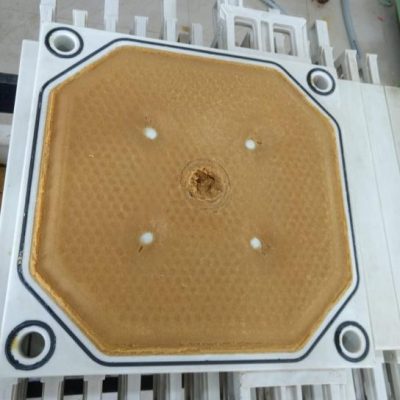

Rice husk agro-waste is chemically treated to produce unbleached cellulose pulp, which is then bleached and hydrolyzed to create microcrystalline cellulose slurry. This slurry is pressed into cakes and dried using spin flash and open-air drying methods.

These products can be marketed and sold through various channels such as distributors, exporters, e-marketing platforms, or directly to customers via a B2B model.

Utilizing rice husk and stubble as feedstock reduces the harmful practice of burning these materials, providing a more sustainable alternative.

The production and sale of value-added products from rice husk and stubble contribute to the project’s long-term financial viability.

Social and Economic Advantages

High Demand

Products like cellulose and silica gel are in demand across industries such as Food, Pharma, Cosmetics, Textiles, and Construction.

Environmental Impact

Utilizing rice husk and stubble as feedstock reduces the harmful practice of burning these materials, providing a more sustainable alternative.

Revenue Generation

These products can be marketed and sold through various channels such as distributors, exporters, e-marketing platforms, or directly to customers via a B2B model.

Financial Sustainability

The production and sale of value-added products from rice husk and stubble contribute to the project's long-term financial viability.

Benefits of Repurposing Rice Husk Utilization

❖ The process will generate cellulose and amorphous silica, to add value to the otherwise wasted rice husk, while minimizing its environmental footprint.

❖ Agro waste such as rice husk and Stubble can act as an alternate feedstock to reduce wood use and reduce Pollution and Deforestation.

❖Agro-waste processing using the proposed process can be used sustainably to produce high-quality cellulose powder.

❖ Rice husk (containing amorphous silica) can be used as feedstock and needs less energy for silica isolation using least no of processing steps.

Major Outcomes

-

Two farmers benefited from the effluent supply and are interested in collecting more from our facility.

-

One of the nearby rice mill has benefitted monetarily as well as environmentally from procurement of rice husk from them.

-

One local youth employed on contract basis for supporting the scale up activities of rice husk processing.

Glimpses